I finished replacing the raw water pump on the generator. I don’t usually leave jobs half done, but I ran out of time and came back to a messy engine room. Over-all a pretty straight-forward affair. The nut and gear were extremely difficult to get off. I used a heat gun and a vice grip, a hammer and a pry bar. Eventually, I just wailed on it to loosen it. I think I damaged the nut, as the threads on it and on the shaft are chewed up (which would surprise me, from hammering on it). Regardless, I may not be able to rebuild it without re-threading the shaft and getting a new nut.

I immediately ordered a clamp to attach to my little work bench at home and a set of gear pullers. This is not the last time I will do a job like this.

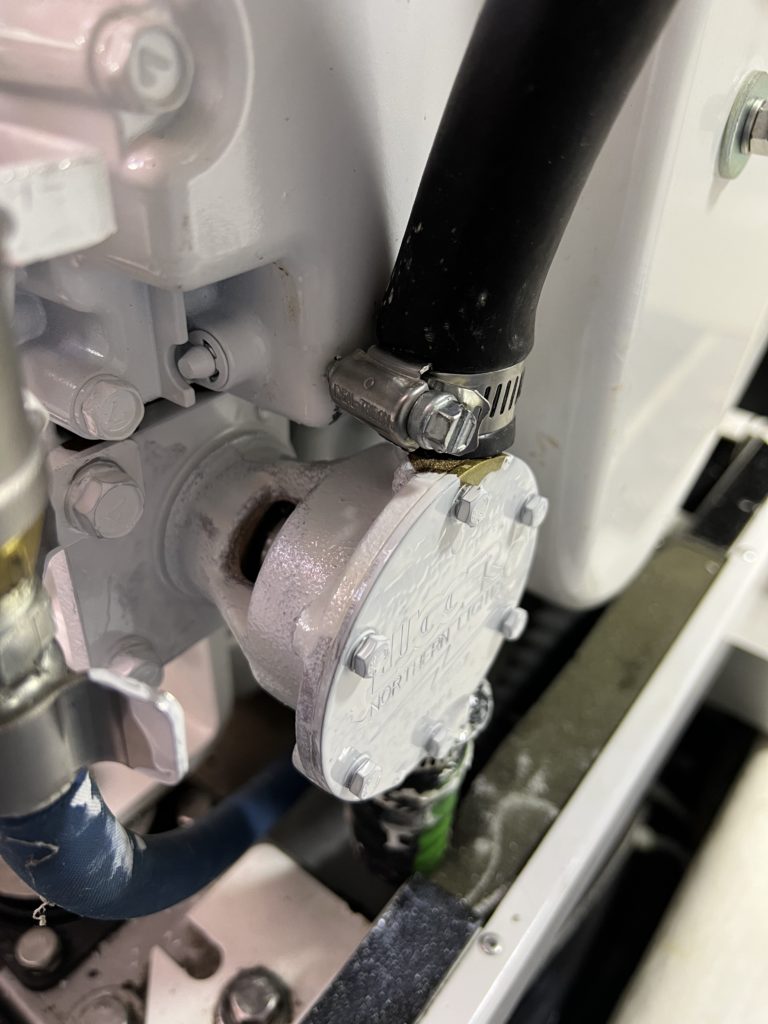

Putting the new pump on took 10 minutes. After painting it, I spent a while cleaning the engine room and finagling the case back together. Feeling pretty good about this one.

I noticed the bit of water on top of the intake hose, but it’s left over from when I disconnected it. So far, there’s no leaks.