We’re up to 219 hours on the main. There’s been a pretty steady stream of gremlins and I’m making progress on the routine maintenance, so let’s jump right in.

Oil Changes

Honestly, the oil change system makes this super easy. I changed the oil on both the main and the generator without too many issues. I initially overfilled the main. The Cummins manual says the total system capacity is 17 quarts, but the pan is actually 15 quarts + 1 qt. for the filter and the rest for up in the engine. But, the pump made it really easy to drain down to the right level. Just a brain fart on my part.

The hardest part of the generator was accessing the engine identification plate (behind the coolant overflow bottle) and removing the old filter, which had been painted on. My large filter wrench didn’t fit the small filter, so I wound up mangling it off with a channel lock. While the transmission and main engine oil have ball valves for controlling flow to the oil change pump, I could not find one for the generator. The hose from the generator oil pan goes through a couple of fittings/couplings that look like some kind of back-flow controller, so I’m guessing that’s why.

Minor Stuff

- Replace a faulty cabinet limit switch (so the light turns on when you open the door).

- Bottom service by John with Reliable Dive. Liberty Bay gunk builds up fast and John does solid work. He discovered that I don’t have room for a shaft anode, so Trevor sent me a shaft brush.

- Signed up for the Boat Electronics 101 course on boathowto.com. So far I’ve found it super useful for filling in several of my various knowledge and theory gaps. Bonus: Nigel Calder personally answers your questions.

- Added a rack for the Kayak. These were backordered for months. They’re over-priced and I probably could have figured out a way to fabricate something. But, sometimes you just throw money at a problem.

Blaine Trip

I took the boat back up to Blaine so Dave Rasmussen could work on it. He’s the same guy who commissioned it and does super high-quality work with innovative customizations. The boat will be up there for the next few weeks while we get several items sorted.

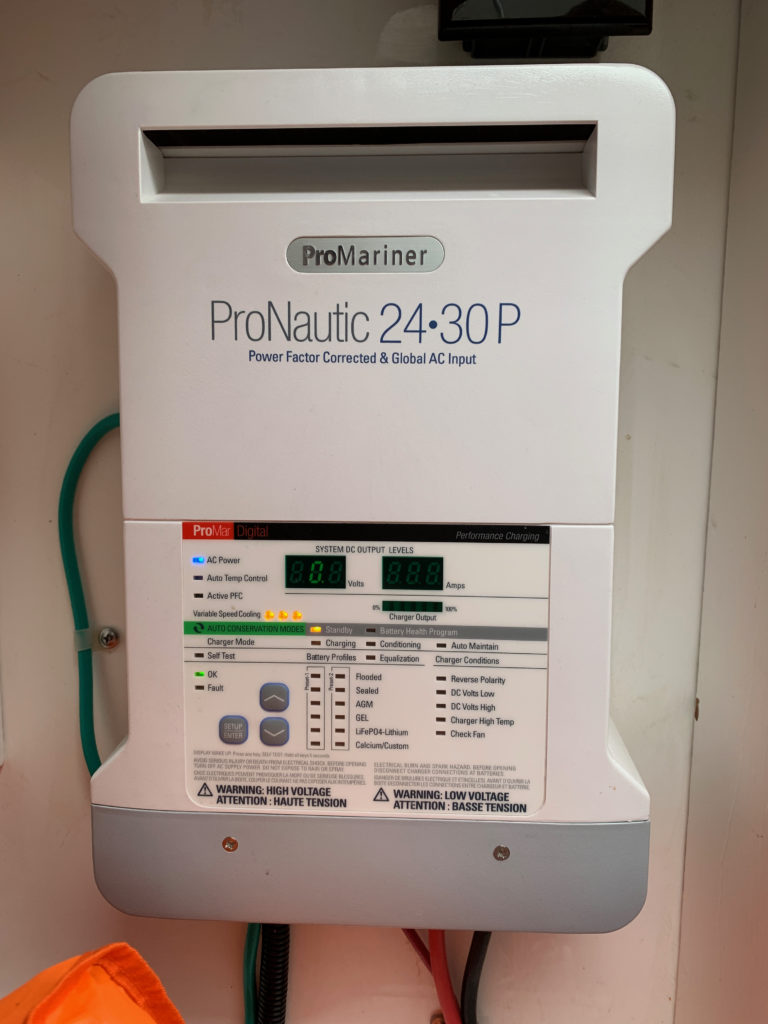

24V Charger Failure – Turtle is a 12v boat, but has two 24v battery banks for the thrusters and windlass. These are charged by a 24v charger that runs off of AC power (A DC-to-DC system would have been much simpler here, but I’m not going to rewire at this point). I noticed a while back that the fan was running a lot and I confirmed earlier this fall that it cycles on at full power even when the charger is on standby. I called ProMariner and they confirmed that it’s faulty, but they wouldn’t send me a replacement, instead insisting that I send it in for diagnostics. So, I filed the RMA paperwork and Dave will pull it out while the boat is in Blaine. This picture shows the fan on high when the charger is in standby and the case is 56 degrees Fahrenheit. This could be the root cause of my ELCI issues, which Dave is also going to spend some time on this month.

Engine Smoke – This was kind of disturbing. The boat has always made a weird sound when it hits about 2250 RPMs, which I assumed was the turbo. I noticed on the trip north that if you get the rpms exactly right, it kind of cycles on and off and makes a rattling sound. That was on Monday. Then on Wednesday, I noticed engine smoke when it was under load. I did some documentation and Dave will look into it. There’s no reason an engine with 200 hours should be producing smoke. Dave doesn’t think it’s serious, but was a bit mystified why it would start on the second day. I was cruising harder than usual to make my weather windows, but the boat should be able to go all day at 2700 rpm.

Replace Ultraleather in Pilothouse – This was the original reason for the visit. The dash is bubbling up and the headliners are drooping. The factory just cut some corners, so North Pacific is replacing the defects.

Widen the Midship Bunk – Turtle has an “L” bunk configuration, with a full-sized bed on the bottom and a single on the top. Not only does this cause the family “not fair” klaxon to sound, it really isn’t a great configuration as the kids grow. In retrospect, we should have had two twin-sized bunks in a regular aligned configuration (along the hull) with more floor space. But, given what we have, we’re going to widen the top bunk. This has the side effect of crowding out the already very small standing space (if the bunk comes out to the door, the distance between the forward hanging locker and the bunk is like 24″). So, Dave came up with the idea of making it retractable, similar to the pilothouse bench that converts into a berth. We’ll have a couple of expansion blocks that we can keep under the lower bunk and convert the bed from a single (with floor space) to a twin (with play space above and a privacy cave below, for our cellar dweller). We love this idea and are super excited to see how it comes out.

If There’s Time Stuff

- Add a foot rest to the pilothouse bench.

- Repair the blackwater tank gauge (the solder on the starboard foil sensor came loose)

- Install the shaft brush.

- Apply a coat of wax.

- Repair a couple of gelcoat chips.

Cruising Notes

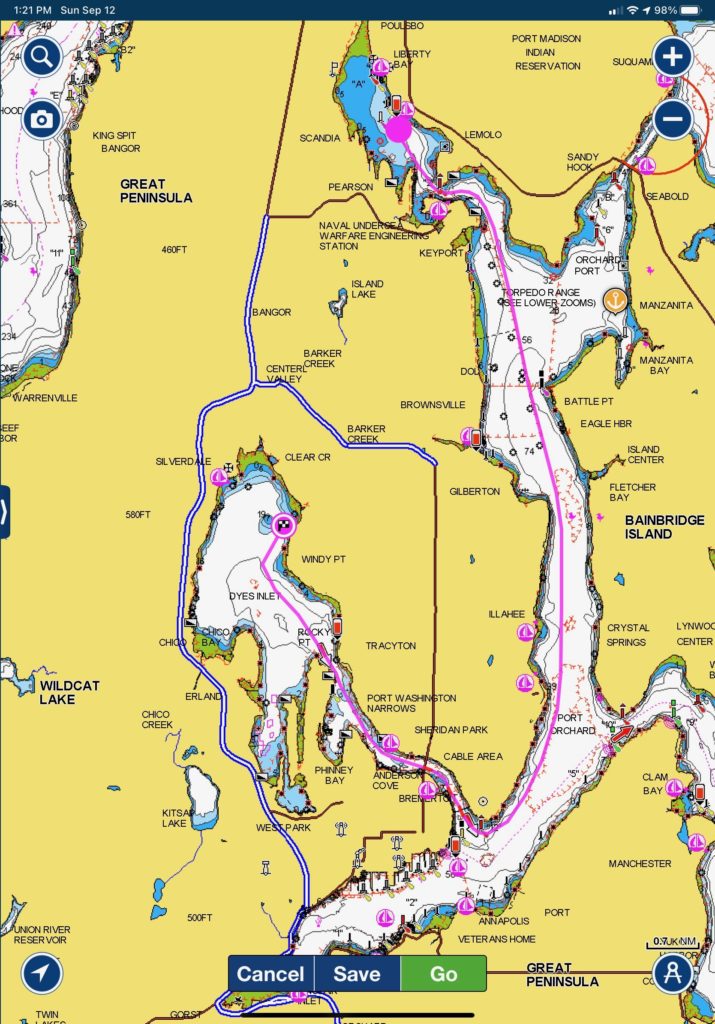

We’ve covered a lot of water this fall, including a fair amount of single-handing by me with and without the kids. We went to Dyes Inlet, Port Orchard, Downtown Seattle (Bell Harbor Marina), Edmonds, and 100 miles from Liberty Bay to Blaine. We filled up twice, including 350 gallons in Brownsville, which took a couple of hours with a dispenser with no lock on the handle (!). First world problem…

The trip to Blaine was interesting as I did it in the midst of a series of nasty low pressure systems that brought heavy wind and rain. I used a weather router to confirm my own planning and spent an extra day in LaConner waiting out the 50 kt gales, but it all worked out. Rich (The Weather Guy) turned around a float plan on short notice and checked in with me every day. Very nice to have some expert backup.